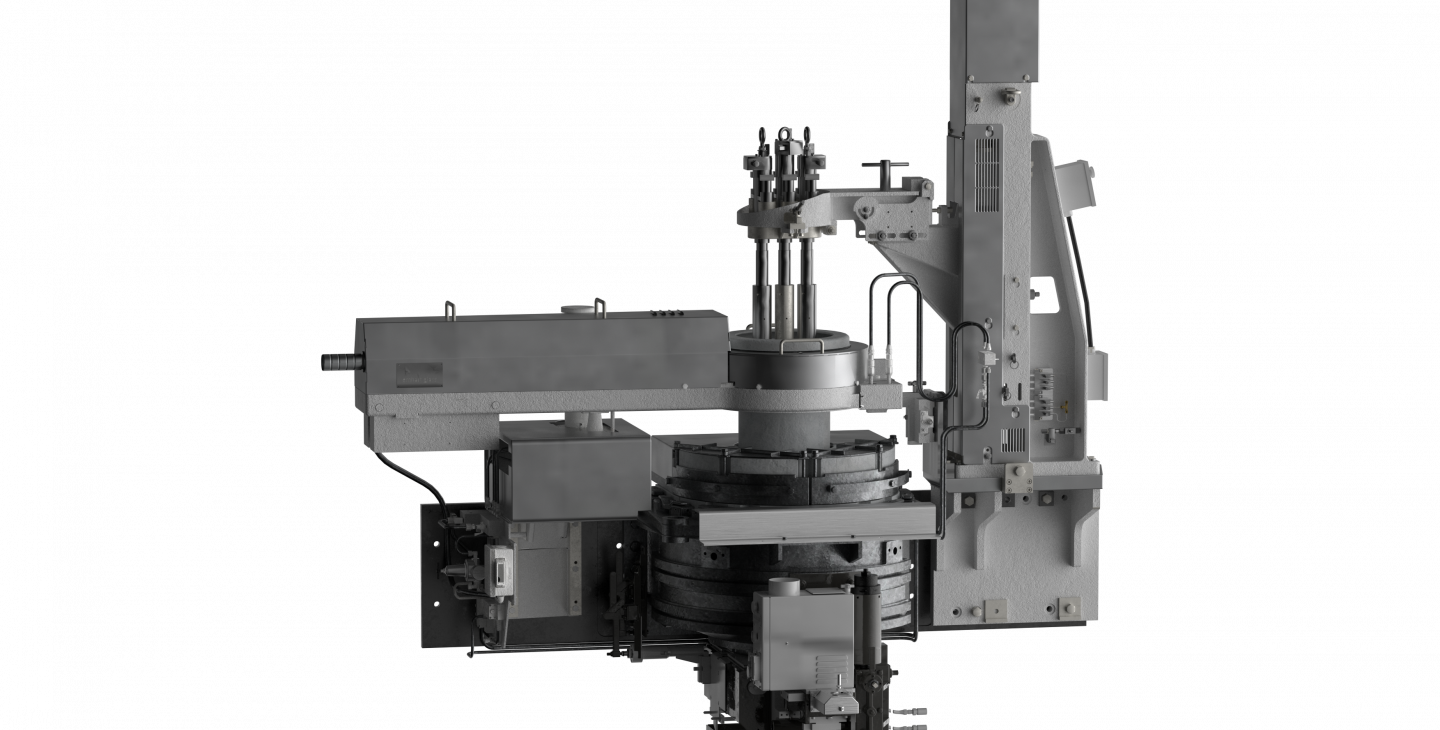

Customized Gob Forming

The Servo Feeder System offers the ability to improve production quality and customize the gob forming. The Feeder System includes the Feeder Plunger, Tube Height and Rotation and the Shear Mechanism as well as the optional Metering Spout System. The Metering Spout features reduced servo tube sensitivity and improved thermal and weight varations. This degree of control with the servo-driven gob forming equipment reduces glass loss and optimizes feeder and shear performance. The Feeder System is available fully integrated into the FlexIS Process Control System and also as a standalone version interfaces with existing non FlexIS timing systems.

Features and benefits

- Improves gob forming and loading at rates from 1 to 240 cuts/minute

- Speeds job changes and allows quick save & recall of all critical job information

- Provides high torque needed to make custom feeder plunger motions

- Improved gob weight control

Specification

- Covers tonnage ranges from 5-200 m TPD

- Fits 81, 555 and 585 spout assemblies

- Advanced servo technology

- Cut rates from 1 to 240 cuts/minute

- Software cam profiles can be adjusted while feeder is running

- Includes metering spout system for: reduced tube sensitivity, improved thermal and weight variations, improved loading

- High dynamic servo motors for precise plunger motion

- Bucher Emhart Glass standard FlexIS technology

- Installs into new or existing applications

- Available with standalone or integrated controls

Downloads

TNB209 - 570 Servo Plunger Mechanism

PDF | 19.10.2020

TNB073 - 565 Servo Shear.pdf

PDF | 23.09.2020

TNB307 - 575 Dual Drive Shear_RevA.pdf

PDF | 13.02.2025