Create and maintain your desired gob automatically

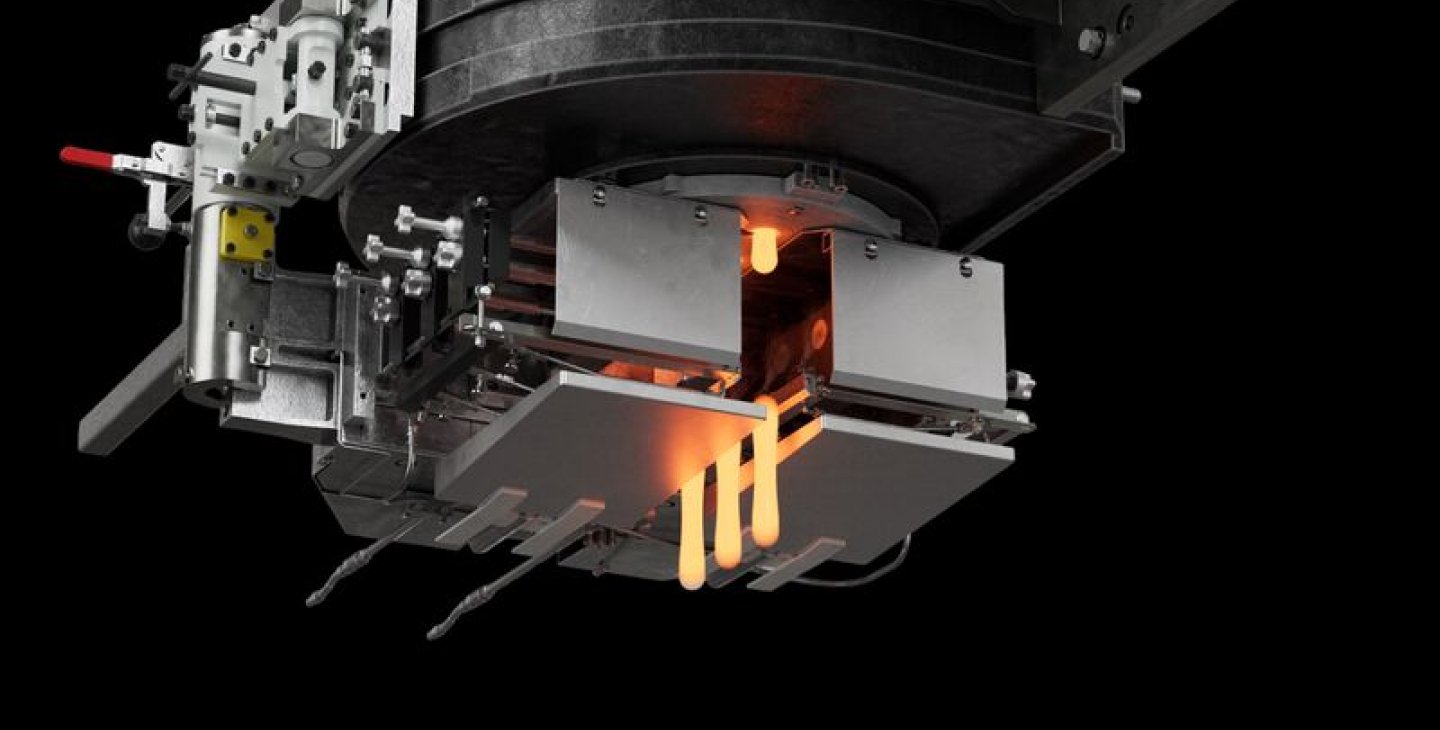

The SMARTFEEDER is the latest development to automatically adjust the gob forming process to your needs, consisting of:

- GobRadar as a measurement system

- Advanced gob forming hardware - 575 Dual Drive Shear and Multi-Drive Feeder

- Gob Control Closed Loop

SMARTFEEDER improves process stability, enables easier start-up after job change and facilitates multi-article production.

SMARTFEEDER allows you to define parameters for your desired gob design. The Gob Control Closed Loop then adjusts any deviations per cavity and for multi-article production.

Improving efficiency and speed

Reduced job change time. Improved start-up after a job change. Gob parameters from the previous jobs can be stored and are achieved automatically even under different conditions

Overcoming the knowledge gap

Less reliance on experienced operators to adjust the gob forming process. Automatic adjustments are independent of operator experience and result in a more consistent forming process.

Greater control from the start

Gob weight and length are automatically adjusted for each section individually. Easy gob forming for single and multi-article production.

Greater consistency across jobs

Gobs are perfectly replicated even under varying conditions. There is no need to change the calibration between jobs unless specific conditions within the feeder have fundamentally been changed.