Reliable, flexible and expandable

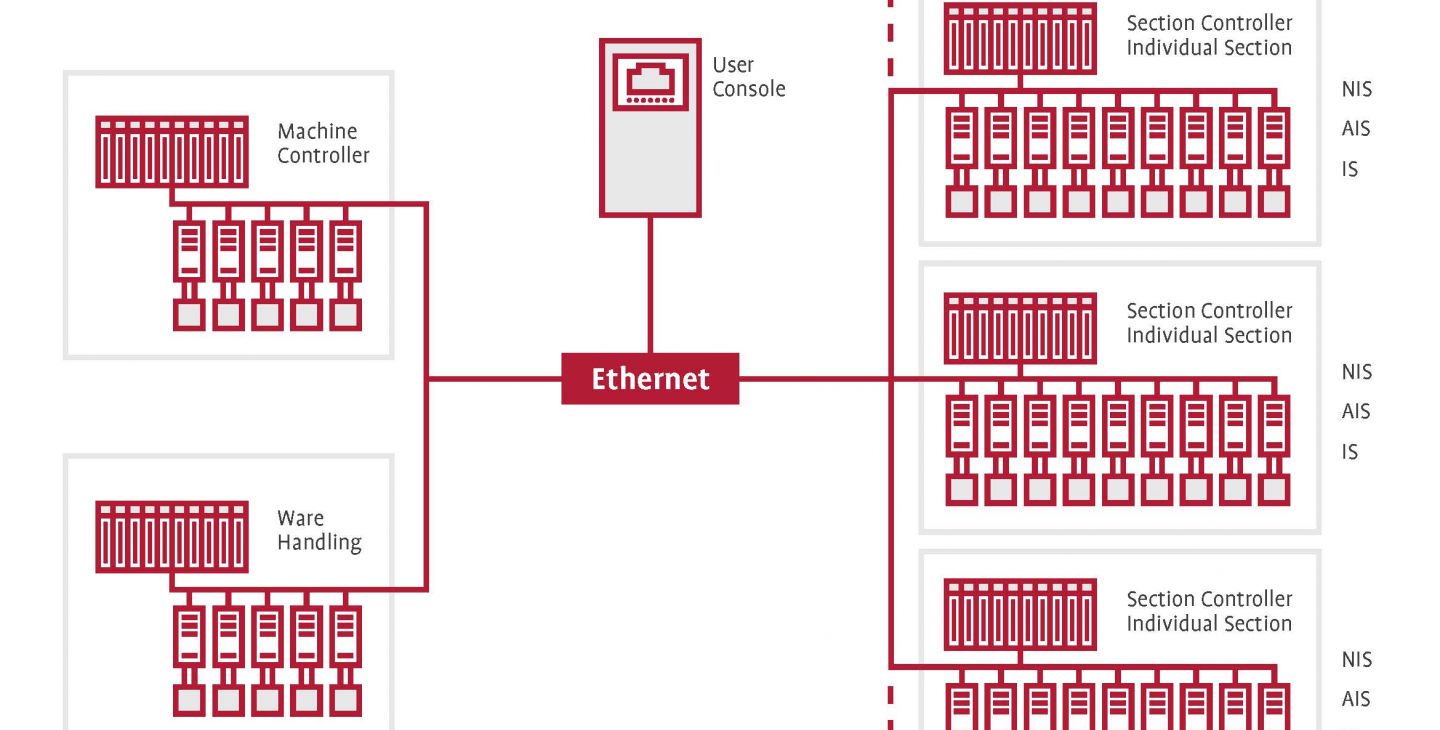

The FlexIS Process Control System is the core component that makes automation of the container forming process possible. In addition to controlling a forming machine, FlexIS is capable of fully driving all mechanisms from feeder to stacker.

Latest developments include closed loop control technology, giving real automation solutions to the glass forming process. Much more than a forming control system, FlexIS is conceived as a full process control system capable of directing all of the various events and actions required to produce high quality glass containers. The FlexIS system is designed to be the neurological center for the glass container production process.

Features & Benefits

Safety

- New safety mode: Manual Mode which offers speed supervision for Servo Invert and Servo Takeout and safe Two Hand Operation for all other mechanisms.

Standardization

- Standardized hardware modules and software functions

- Standardized user interfaces

- Standardized spare parts

Integration

- One control system for the hot end equipment

- Closed Loops

- Blank Side Barrier

- Auto Swab or Swab Robot

- 3-axis Stacker/FlexStacker 2

Reliability

- Industrial grade technology

- Automatic configuration in case of a hardware replacement

Scalability

- Same controls and functions from small pneumatic IS up to high performing NIS

- Wide range of optional equipment

Connectivity

- Full support of all functions through remote access for diagnosis, maintenance and trouble shooting

Downloads

TNB276RevA - FlexIS Controller Replacement

PDF | 18.11.2020

TNB172RevA - Mechanism & Motor Tester

PDF | 20.10.2020

TNB193 - FlexIS Remote Service

PDF | 20.10.2020

TNB210RevA - T600 Replacement with FlexIS System

PDF | 20.10.2020

TNB237- FlexIS Drive Replacement_RevB_0.pdf

PDF | 14.02.2024

TNB238 - FlexIS Remote Service

PDF | 20.10.2020

TNB267 - FlexIS 3 – New FlexIS Control System

PDF | 20.10.2020

TNB218RevD - FlexIS Plunger Up Control

PDF | 30.11.2020

TNB248 - FlexIS Basic Closed Loop Equipment

PDF | 21.10.2020

TNB204 - FlexIS Ware Handling Supervision – WHS

PDF | 21.10.2020

TNB220RevE - FlexIS Blank Cooling Control

PDF | 20.11.2020