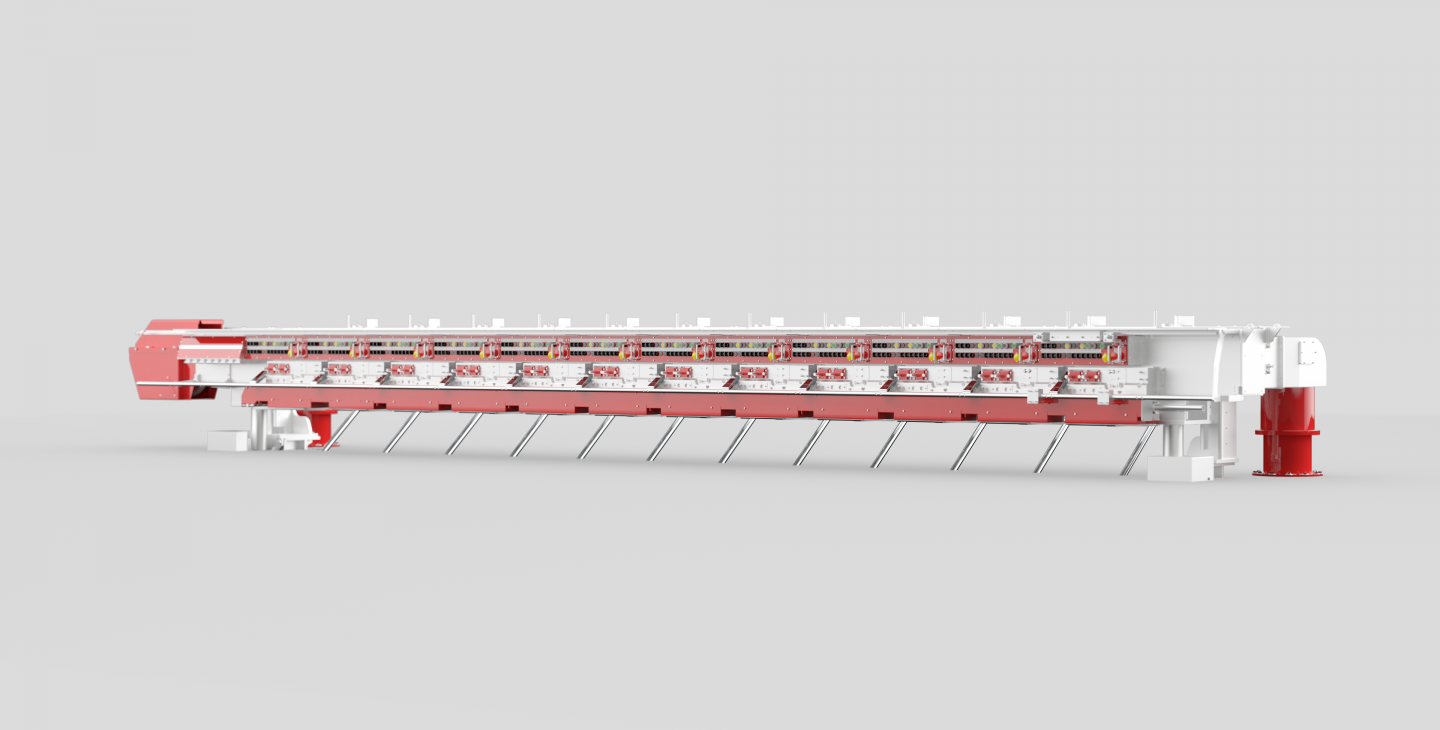

The Emhart steel FlexConveyor aims to combine all the different customer needs.

As a standard it improves the stiffness, reduces the reach distance, optimizes the wind box for equal flow with an option for two on/off controls, integrates the pusher cables and provides a height-adjustable dead plate. To improve the ease and safety of blow side accessibility the FlexConveyor has an integrated ladder.

Dual Row Operation

Pharma Type II sodium calcium glass containers need a surface treatment to achieve the specified hydrolytic stability. Larger and faster machines have pushed existing dosing equipment on the machine conveyor to its operating limits. The Emhart dual row FlexConveyor uses the FlexPusher and allows changing between single and dual row within minutes.

Features

- Steel girder

- Integrated ladder

- Dually controlled wind box

- Height adjustable wind box

- Closer access to blow side

- Easy and quick to convert from: single row to dual row

- Standard for all Emhart forming machines

Benefits

- Increased robustness

- Safe and easy access to blow side

- Balanced flow & adjustable pressure profile

- Easier blowside swabbing

Downloads

TNB153 - Precision Conveyor Chains – Key for better Ware Handling

PDF | 21.10.2020

TNB202 - Dual Row Ware Handling

PDF | 21.10.2020

TNB216 - FlexConveyor

PDF | 21.10.2020