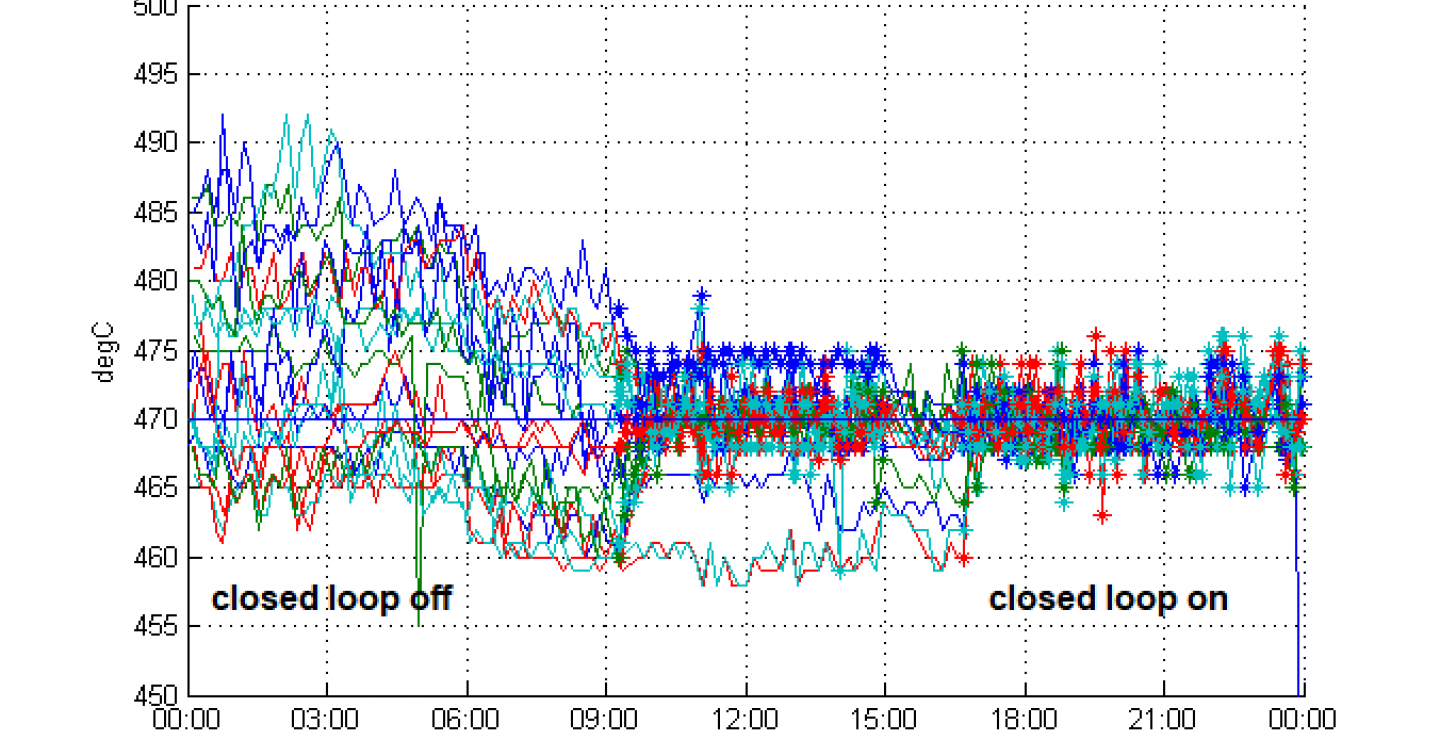

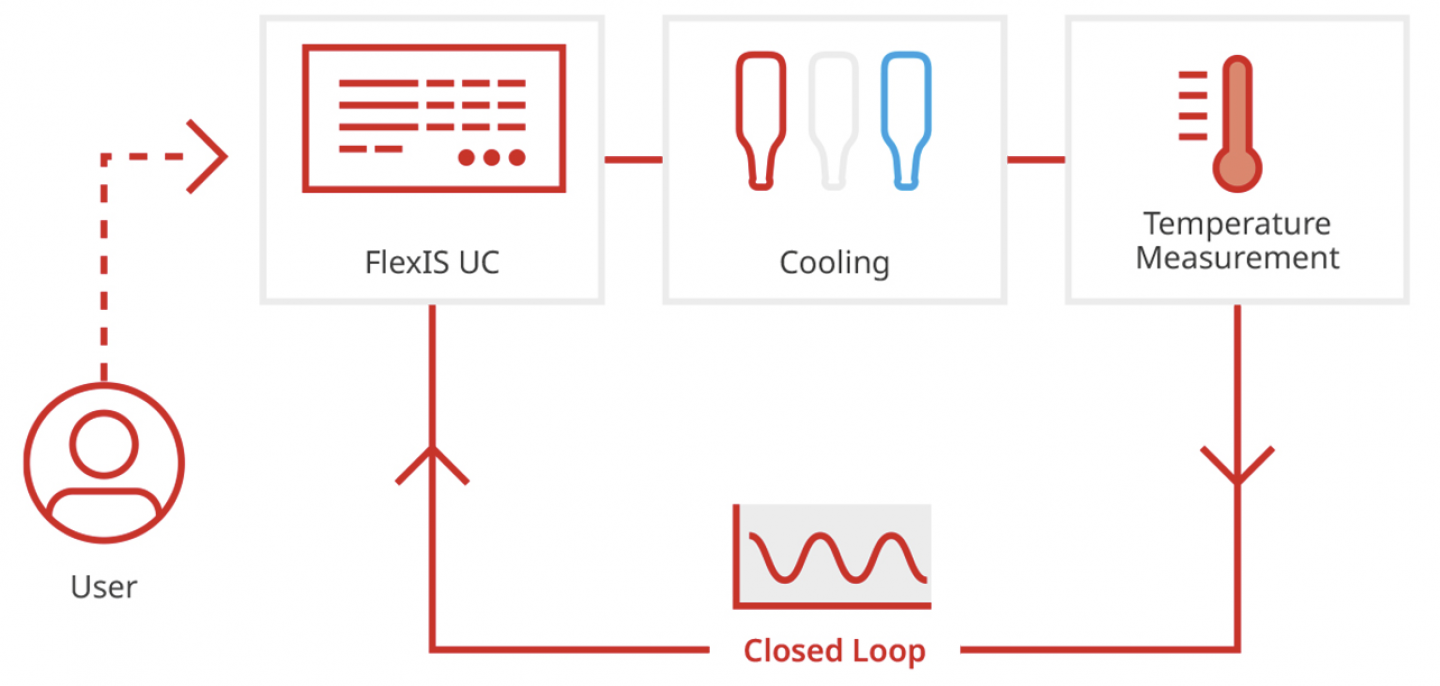

FlexIS Cooling Control is a bundle of closed loops maintaining important temperatures on the desired level. All of these closed loops adjust the related cooling in the forming machine. They use information from a temperature measurement system.

Adjusting blank cooling

FlexIS Blank Cooling Control BCC automatically adjusts the cooling of the blank mold halves so that the desired temperatures are maintained. Depending on machine type and configuration, up to 72 mold halves are monitored and adjusted. By continuous adjustment, the mold temperatures can be kept within tight limits over day and night. The system also provides big help for starting up a machine after job change.

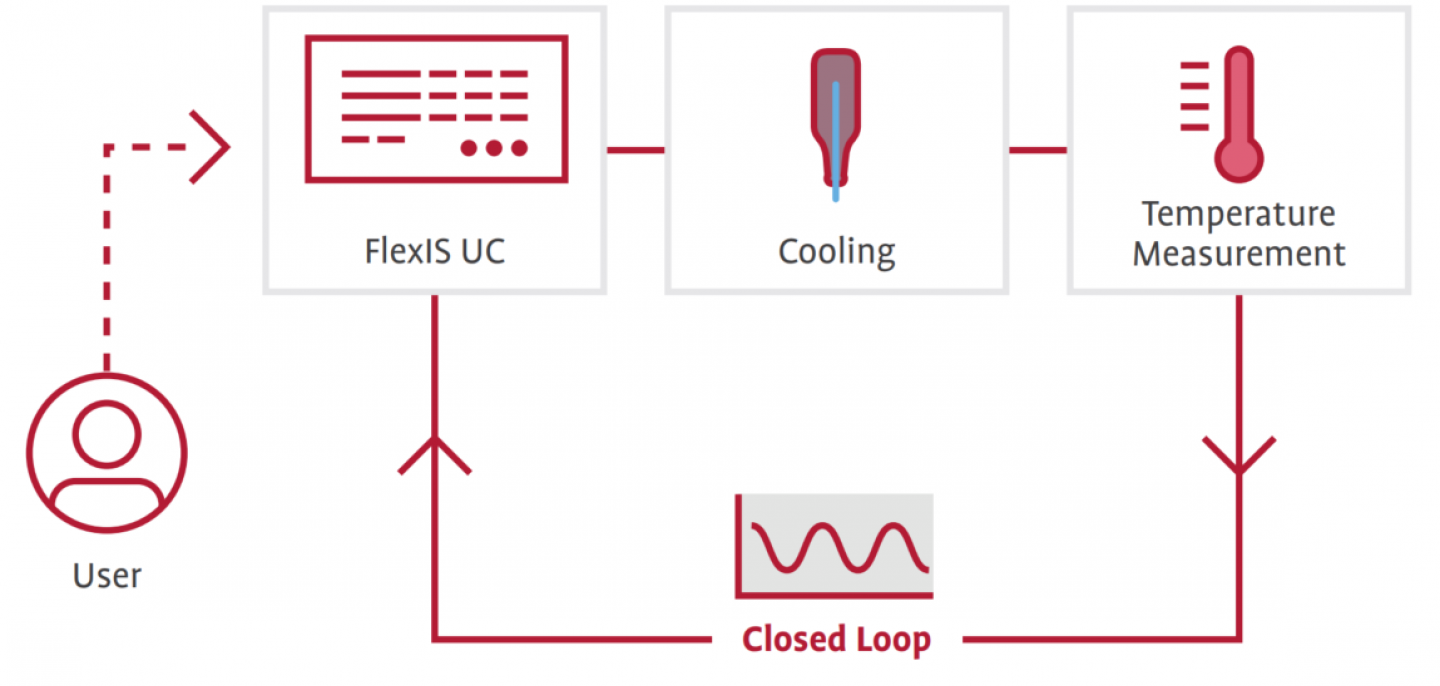

Adjusting plunger cooling

FlexIS Plunger Cooling Control PCC automatically adjusts the cooling of the plungers so that the desired plunger temperatures are maintained.

Depending on machine type and configuration, up to 48 plungers are permanently monitored and adjusted to changes of surrounding parameters. This leads to more stable production runs and also prevents quality problems inside the container and finish.

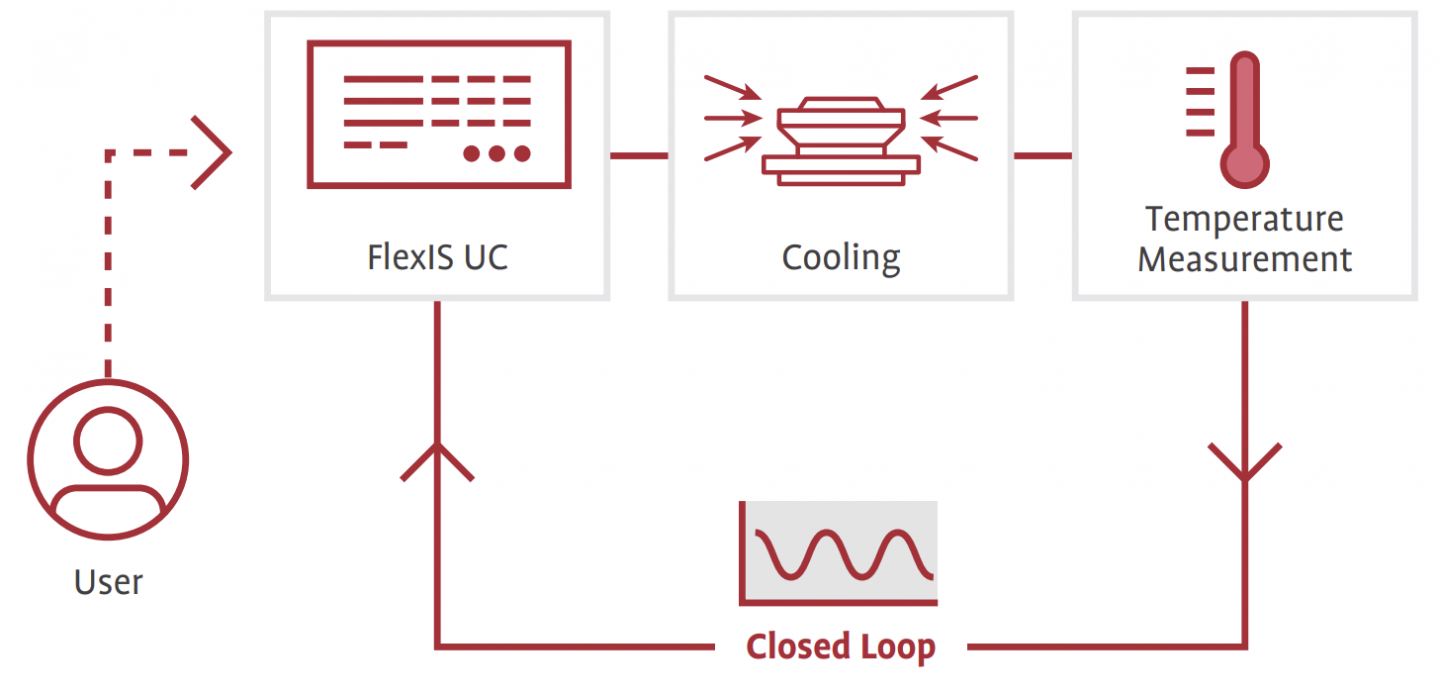

Adjusting neckring cooling (new 2024)

FlexIS Neckring Cooling Control NCC automatically adjusts the cooling of the neckring halves (right/left) and keeps the neckrings on the desired temperature. This is particularly beneficial for jar production.

- The FlexIS Cooling Control closed loops are fully integrated into the FlexIS controls. All settings are stored as job/article data.

- Temperatures of the blank molds, plungers and neckrings are kept on the desired temperature by automatic adjustment of the related cooling.

- The closed loops are not only beneficial in steady state production, but also reduce the start up time after a job/article change.

- Limits for the cooling adjustments can be set. When a limit is reached, an alarm can be displayed so that the operator is made aware of the situation.