Adjusting bottle spacing

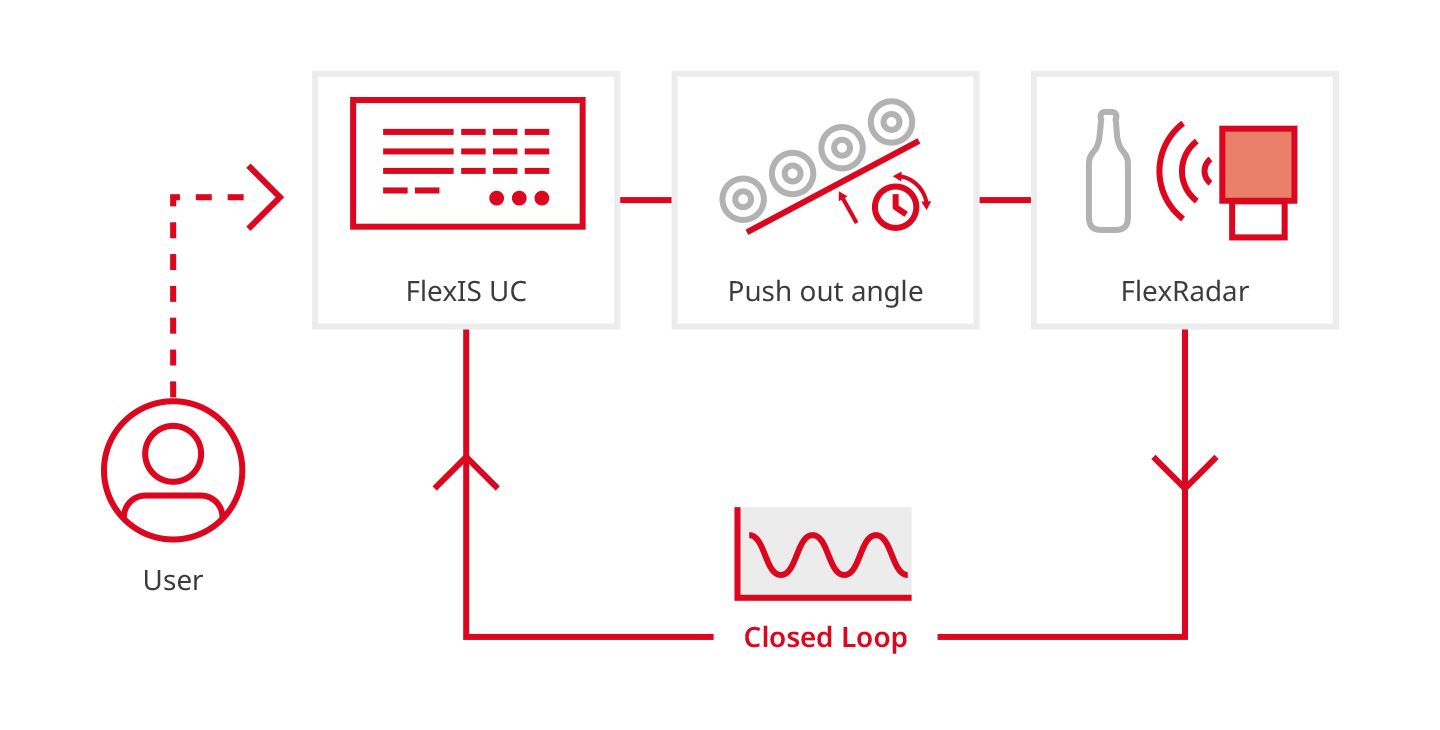

FlexIS Bottle Spacing Control automatically adjusts the placement of the containers on the conveyor so that an equally distributed ware sequence is maintained.

FlexIS Bottle Spacing Control uses information from the FlexRadar forming process monitor system. For each bottle, a deviation value to the ideal position on the conveyor axis is transmitted and used to adjust the Pushout timings.

The closed loop averages the position deviations for each section and calculates a correction for the Pushout and related events, so that the bottles maintain equally distributed along the conveyor axis.

By the automatic adjustment, an equally distributed ware sequence is achieved and maintained, also when pusher parameters are slightly changed.

Downloads

TNB248 - FlexIS Basic Closed Loop Equipment

PDF | 21.10.2020

TNB250RevD - FlexIS Bottle Spacing Control

PDF | 30.11.2020