Advanced Pneumatic Glass Container Forming

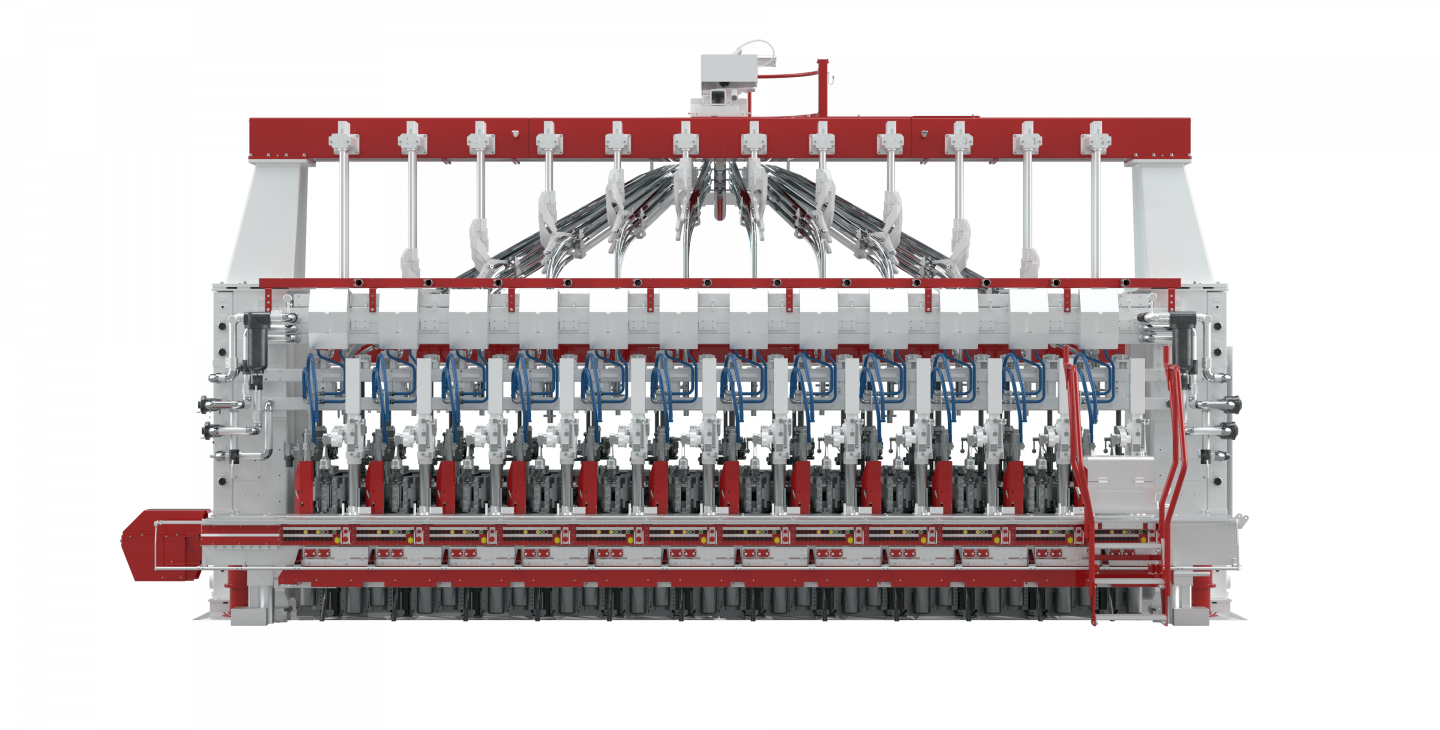

The AIS machine is recognized by the industry as the superior performer among pneumatically driven glass container forming machines. A combination of valued features, including parallel Mold Open and Close MOC mechanism, pneumatic operation, high efficiency VertiFlow cooling, and built-in flexibility, make the AIS machine top of its class.

The next generation AIS is built to give glassmakers even more, with many new features designed to deliver enhanced performance, better production, and reduced maintenance on the forming line.

| AIS | 6 1/4" Double Gob | 4 1/4" Triple Gob | SG | ||||||

|---|---|---|---|---|---|---|---|---|---|

| B&B | P&B | NNPB | B&B | P&B | NNPB | B&B | P&B | NNPB | |

| Min. Height under Finish | 120mm | 80mm | 80mm | 120mm | 80mm | 80mm | under development | ||

| Max. Height under Finish | 412mm | 380mm | 380mm | 369mm | 350mm | 350mm | |||

| Max. Body Diameter | 121mm | 121mm | 121mm | 76mm | 76mm | 76mm | |||

| Max. Finish Diameter | 48mm | 105mm | 38mm | 48mm | 70mm | 38mm | |||

Note: AIS new standard with +65mm increased section frame height and 4000 series plunger mechanism.

Standard Features

- FlexIS 3 Control System

- Servo electric gob distributor

- Bezier delivery

- Full Parallel Blank and Blow mold opening

- Quick Change Plunger Mechanism 8” stroke DG/TG/SG

- Enhanced 26 lines Electric Pneumatic Valve Block (EPVB)

- Servo Electric invert

- Servo Electric take out

- FlexPusher

- InVertiFlow blank mold cooling with individual cavity control

- Traveling radial cooling with individual cavity control

- VertiFlow assist

- FlexIS manual mode

- FPS Valve Technology for plunger up and counter blow

- VertiFlow Blank Mold Cooling with Individual cavity control

- Neck ring cooling

- VertiFlow blow mold cooling

- High Low deadplate cooling

- Vacuum assist blow side

- Blank side Barrier

Optional Features

- FPS Final Blow

- Blank side lifting device

- Blow side lifting device

- Plunger Process Control PPC (enabling closed loop control)

- Temperature Control System TCS (enabling closed loop control)

- Temperature Control System (TCS) or BlankRadar - enabling closed loops

- Variable Center Distance tong head VCD TG

Downloads

BR0066 AIS

PDF | 08.03.2022

TNB257RevC - Blank Side Barrier.pdf

PDF | 10.01.2025

TNB289 - New Standard for all BEG Forming Machines

PDF | 19.10.2020

TNB255 - VertiFlow Assist for AIS machines

PDF | 20.10.2020

TNB280 - Constant Cone Bezier Delivery

PDF | 26.10.2020

TNB086 -Two-Way Air Operated Funnel Mechanism

PDF | 28.10.2020

TNB240RevC_Blank Side Overhead Panel

PDF | 18.09.2024

TNB292 - 4000 Series Plunger Mechanism

PDF | 11.11.2020

TNB081 - AIS Neck Ring Cooling

PDF | 11.11.2020

TNB033RevB - Pantograph Baffle Arm

PDF | 12.02.2021

TNB031RevB_DE - Baffle Mechanism IS 5 ½” & 6 ¼” and AIS

PDF | 15.02.2021

TNB295 - Roller Bearing Neckring Mechanism

PDF | 27.05.2021

TNB311 - IS standardization.pdf

PDF | 20.04.2023

TNB317_Redesigned Pantograph Baffle Mounting Parts

PDF | 21.12.2023

TNB318 VCD Tong Head.pdf

PDF | 11.01.2024

TNB321 - V-Baffle.pdf

PDF | 17.06.2024

TNB322 - Blow Side Lifting Device_3.pdf

PDF | 17.06.2024

TNB323 M-Bracket.pdf

PDF | 01.07.2024

TNB328 Modular Air Supply piping.pdf

PDF | 15.01.2025