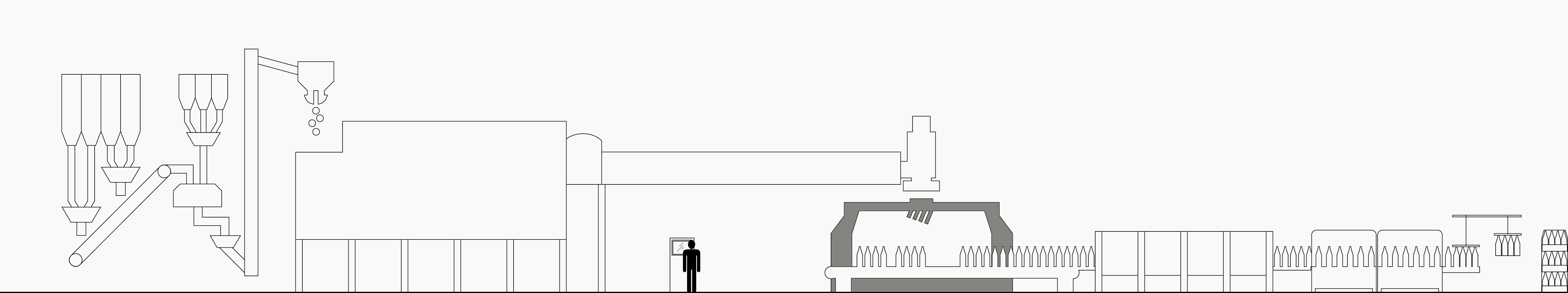

1.

The batch plant (1) stores the raw materials used to make glass. They include cullet (crushed recycled glass), quartz sand, soda, calcite, dolomite and feldspar. Cullet is used in variable quantities, based on availability. In some areas, it might make up 20–30% of the batch, but in developed countries the proportion can be as high as 60–90%.

2.

To achieve different colours, chemicals such as iron oxide (green), sulphur (amber) and cobalt (blue) are added. The materials are carefully sorted and mixed according to a precise formula to form the batch, which is taken by a conveyor belt to the batch charger (2), sometimes known as the ‘dog house’.

3.

The batch charger continuously and steadily feeds the batch into the furnace (3), where it is heated by electrical, gasor oil-burning systems to a temperature of 1550–1600ºC (2822–2912ºF). To save energy and reduce environmental impact, waste gases are used to preheat the air inside the furnace.

4.

As the melted glass leaves the furnace, it is distributed to the forehearth (4), which ensures that the molten glass is heated evenly throughout. This process is known as glass conditioning.

5.

The next stage is gob forming (5) – turning the molten glass into shapes that can be moulded. The glass enters a feeder, where a plunger pushes it down through a narrow tube. As the stream of glass emerges from the tube, it is sheared (cut off) to form a lump of glass known as a gob. In essence, the design of the plunger-feeder has not changed since it was launched by Hartford-Fairmont (the forerunner of Emhart Glass) in 1918.

6.

Now comes container forming (6), the heart of glasscontainer production, where the gob is manipulated and/or blown into its final form. Different forming techniques are used to make different types of container: blow-and-blow is primarily used for bottles, while press-and-blow is mainly used for jars.

Both processes comprise a ‘blank side’, in which the gob is formed into a partially completed form known as a ‘parison’ and a ‘blow side’, where the final shape is achieved. The container starts off upside down and is gripped by the ‘neck ring’, which allows the parison to be inverted as it moves from the blank side to the blow side.

In the blow-and-blow process, the sheared gob is blown downwards to form the ‘finish’ (outer surface) – this is called the ‘settle blow’. A ‘counter blow’ from below the gob then creates the cavity within the container. Finally, the parison is then inverted and blown into the ‘blow mould’ to form the final shape.

In the press-and-blow process, the parison is formed by a metal plunger, which presses the molten glass out to fill the blank mould. The parison is inverted and then blown out as in blow-and-blow.

Production lines for glass containers typically feature more than one container-forming unit, or section. Emhart Glass is well known for developing the individual section machine, or IS machine, which allows each section to be maintained independently of the others. Modern IS machines comprise as many as 12 sections.

As well as producing one container at a time (known as single-gob production) they can work with multiple gobs to make two, three or four containers simultaneously (referred to as double-gob, triple-gob and quad-gob production respectively).

7.

Once they are fully formed, the containers are removed from the IS machine in the take-out stage (7). Then, an automated pusher transfers them to the conveyor (a conveyor belt). Functions handled by pushers and conveyors that move containers from one stage to the next are sometimes collectively referred to as ware handling. High-speed ware handling while containers are still very hot and fragile is a significant technical challenge.

8.

The wares ride the conveyor to the lehr (8), sometimes called the ‘annealing lehr’. (‘Lehr’ rhymes with the English word ‘here’.) In the lehr, the containers are reheated to about 580ºC (around 1076ºF) and then cooled in the process known as annealing or thermal treatment. Glass naturally shrinks as it cools, which can cause stresses within containers. So the process must be carefully managed and controlled to ensure that the finished containers are as strong as possible.

9.

Emerging from the lehr, the glasswares arrive at the inspection stage (9). Because the glass is now fully cooled, this stage is known as the Cold End – as opposed to the previous stages of production, which are collectively known as the Hot End.

Inspection was once done manually, by eye or with hand tools. Today, fully automated devices use physical and visual tests to check that each container is the right size, shape and thickness. Inspection also picks up checks (small cracks), bubbles and foreign bodies known as stones (usually bits of the refractory that have broken off). Containers that don’t make the grade are rejected.

10.

Finally, the finished containers are carefully packed and placed on to pallets or into boxes (10) ready for transport to the client’s factory, where they will be filled, labelled, sealed and distributed for sale.

11.

The control system (11) controls the IS forming machine. Early glass production was controlled purely mechanically, by skilled engineers making manual adjustments. Later, electronic controls were developed, and today the whole control function can be computerized.