Enhanced Gob Loading

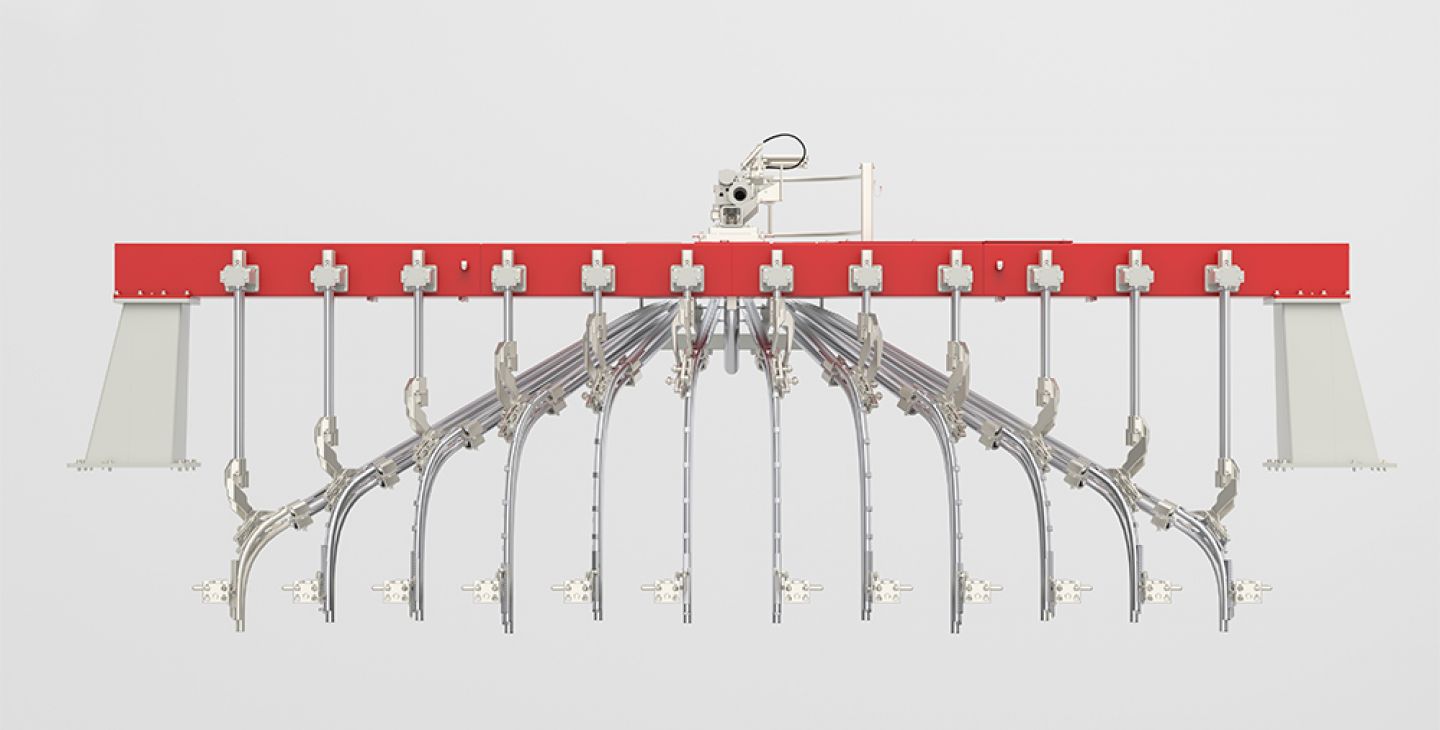

Constant Cone delivery is the latest Bucher Emhart Glass development for optimal gob loading. The Constant Cone delivery family is based on a constant trough angle of 28° and covers the full range of forming machines (NIS, AIS and IS) for all available center distances. The newly developed Bézier equipment, in conjunction with the constant cone geometry, provides enhanced gob loading.

Optimization criteria are based on:

- Minimize centripetal accelerations

- Reduce gradually the radial accelerations to zero

- Generate a smooth landing zone

- Increase the length of the deflector profile at the upper end

Smaller curvature design

- Reduced gob entry angle variations

- Reduced gob shape variations

- Increased loading stability

Smoother entry curve path

- Reduced impact forces

- Reduced Normal forces

- Increased loading stability

- Longer coating lifetime

- Reduced gob shape variations

Smaller impact and nominal forces

- Less kinematical energy consumption

- Higher loading speed

- Better gob shape

Uniform normal force distribution on all sections

Reduced gob speed and gob shape variation from section to section

Downloads

TNB285 - Bezier Scoop Family for constant cone delivery

PDF | 22.10.2020

TNB235 - Constant Cone Delivery

PDF | 26.10.2020

TNB280 - Constant Cone Bezier Delivery

PDF | 26.10.2020

TNB044 - Deflector Series 18000

PDF | 03.02.2021