|

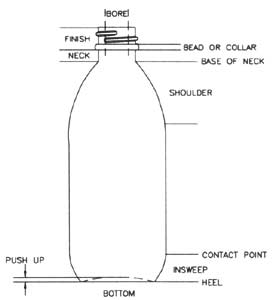

The Finish

This is the top of the container above the neck ring parting

line.

It includes: The Sealing Surface, Bore, Bead or Collar

The Sealing device is in the finish (see next section), also

the bore or mouth for filling and emptying. The bead or collar

is used to assist in transferring the parison into the blow

mold.

The Neck

The part which extends from the parting line to the curve at the base of the neck.

The Shoulder

This extends from the base of the neck to the straight part of the body.

The Body

The main part of the container which holds the product.

The Bottom

The part of the container on which it stands when upright.

Insweep

The curve between body and bottom which helps to improve glass distribution and thus

strength.

Push-Up

The center of the bottom which is raised up to provide a flat surface on the outer edge of

the bottom and thus provide a firm seating.

When producing a glass container,

various items of mold equipment are used as follows: Blank Mold, Baffle, Plunger, Neck

Ring, Blow Mold and Bottom Plate. Where these individual items join, seams are produced in

the container. If the seams do not meet the standard specified, then the container is

rejected. It is, therefore, essential that all mold equipment be examined in the mold shop

and again in the Production Department. It must also be stored correctly and handled with

care at all times.

Neck

Ring Parting Line

Where the neck ring and the blank mold join, there is a seam.

Blank Seam

The blank mold is in two parts. It closes around the neck ring and then receives the hot

gob of glass. Where the two halves of the blank mold join, there is a seam, which can

sometimes be seen as a wavy line on the finished container.

Baffle Mark

The baffle sits on top of the blank when counterblow takes place to form the parison. If

there is a bad match between blank mold and baffle, then a baffle mark or seam may be seen

in the container bottom.

Mold Seam

The blow mold action is the same as the blank except that is closes around the bottom

plate. Where the two halves join, there is a mold seam, which runs vertically on the whole

length of the container.

Bottom Plate Parting Line

Where the blow mold and bottom plate join there is a seam.

|